In the late 1700s, America was growing. Rivers were a major obstacle to communication and land transportation. Bridges were needed for commerce and military protection, but deep water and spring flooding made low, piling-supported bridges impractical.

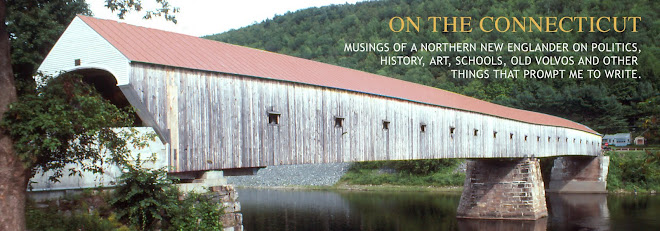

Haverhill MA (click on photo for larger view)

About this time, Timothy Palmer of Newburyport, Massachusetts and Theodore Burr of Torringford, Connecticut adapted European designs and became the first, successful builders of large wooden truss bridges in America. Both of these men were self-taught craftsmen who built numerous covered bridges all over the northeast. Old growth forests provided them with an abundant supply of large timbers.

Once the viability of large wooden bridges was proven, towns, toll-bridge companies and the infant railroad industry began building them in great numbers. By the early 1800’s, contractors were competing for a boom in building contracts.

Ithiel Town of New Haven, Stephen Long of Hopkinton, New Hampshire and William Howe of Spencer, Massachusetts came up with new truss designs that were easier to build than Palmer’s or Burr’s designs. All three patented and then licensed their designs to builders who used them all over America.

Taftsville VT

The unpatented Paddleford Truss was designed by Peter Paddleford of Monroe NH. About 1846, he remodeled the Long truss by replacing the counterbraces with a stiffening member fastened to the inside of the posts at points near the top and bottom chords. This resulted in an unusually strong and rigid structure.

Even with proven designs, bridge building was as much art as science. Bridge builders were ingenious and skilled craftsmen with little formal education. They relied on their training under a skilled master craftsman and their own experience. They knew the characteristics of the materials they worked with — not only how to cut and shape the timbers, but what the load bearing strength was. If there is such as thing as folk engineering, this was it.

Narragansett RI

For me, the most fascinating aspect of New England covered bridges is the superb craftsmanship. Because a wooden truss bridge’s strength comes from being under constant compression, every timber and joint in the timber frame must precisely fit to evenly distribute the load. And a typical 100-foot lattice type bridge could have almost a thousand hand-cut, hand-pegged joints.

There have been numerous stories about why these bridges were covered, but the real answer is simple. They were covered to protect the trusses from the weather. If water was allowed to settle into the joints and rot the wood, the life of the bridge would be short.

The fact that wooden covered bridges built nearly two hundred years ago are still in service is a testimonial to their design and the craftsmanship with which they were built. With good supervision and maintenance many of these will last for years to come.

W. Stewartstown NH

Townshend VT

New Sharon ME

I enjoyed your blog and the old photos/postcards tremendously! Thank you for sharing. I am producing a documentary about New England's covered bridges and I wondered if you could tell me where I might find the images at a higher resolution and to whom I might speak about copyright issues, if there are any. The doc is being produced for public television by Ocean State Video of Rhode Island. Thank you for any help you can provide.

ReplyDeleteSincerely,

Mary Steele

(401) 569-9665